Quality Control

ISO9001:2015 As Guidelines

DLSS is ISO 9001 certified, applying its principles to ensure strict quality control in our manufacturing.

We source from trusted suppliers, ensuring reliable stainless steel pipes that meet global standards.

From raw materials to final inspection, our standardized processes guarantee consistency and performance.

DLSS 4-Step

Quality Management System

From Every Part of The Pipe…

We care about the quality of stainless steel pipes. That’s why we focus on every detail of every component to ensure durability, precision, and superior performance.

Ensures material accuracy and dimensional precision through chemical composition testing (verified by PMI and spectrometer) and size measurement (including OD, WT, length, and pipe end).

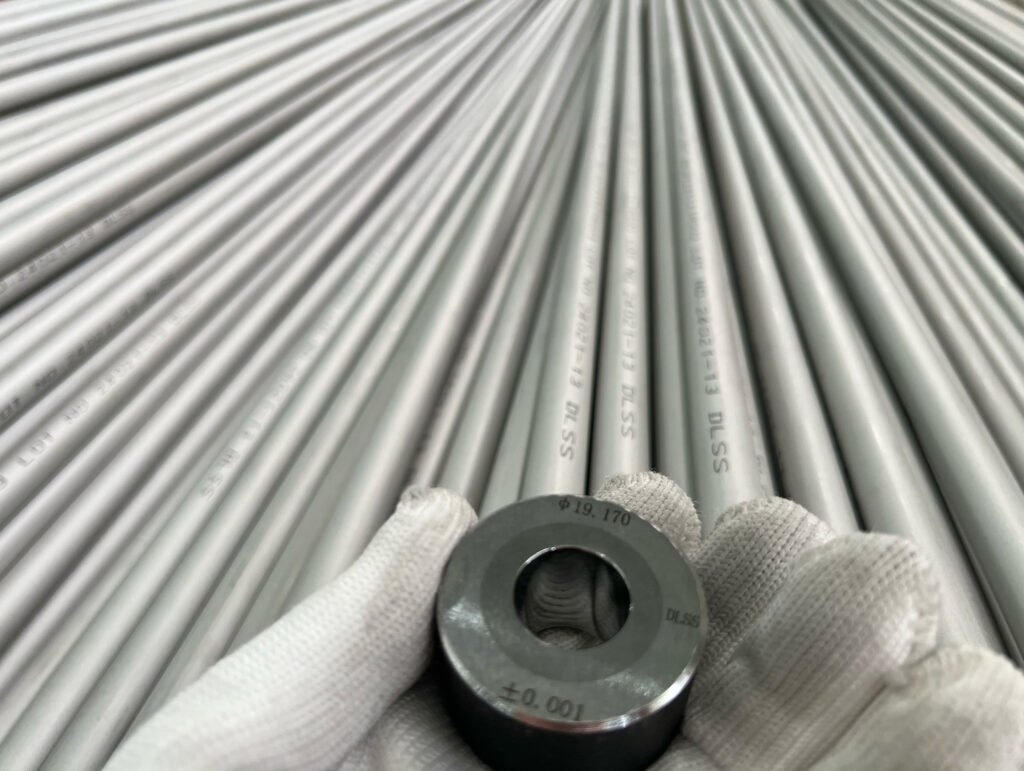

Ensures dimensional accuracy and proper fit through ring gauge testing.

Ensures strength and leak-proof performance under specified pressure conditions through hydrostatic testing.

Ensures detection of surface cracks and defects through Penetrant Testing (PT).

Ensures internal surface quality and detects internal defects through borescope (endoscope) inspection.

Ensures surface quality and detects external defects through external surface inspection.

Sample Tests:

Making Sure Quality of Mass Production

The sample acts as the bridge between premium materials and reliable mass production. Here in DLSS, our unique approach is to test the stainless steel tube sample again and again under the most rigorous conditions, ensuring that all materials meet high-performance standards.

Once the sample passes all tests, the QC team is responsible for recording its specifications and providing a BOM sheet for the mass production procedure.

QQ图片20220128211237-768x576.png)

Want to Be the Next Industry Leader?

DLSS’s stainless steel tubes and services give you an absolute edge over your competitors.